What is CCUS and why is it key for the energy transition?

Experts agree that CO₂ capture, utilization and storage (CCUS) has a vital role in the race to net zero emissions, along with renewables and alternative fuels.

CCUS is a mature and proven technology but it has yet to deliver on its potential. Energy sector analyst Wood Mackenzie expects momentum to turn a corner in 2025, with the focus shifting from projects being announced to real-world executions.

But what does the technology do? And why might it increase our chances of reaching net zero by 2050, as suggested by the Intergovernmental Panel on Climate Change (IPCC) and the International Energy Agency (IEA)?

What is CCUS, and how does it work?

CO₂ capture is a technology that removes CO₂ from fossil-fuel-powered sources such as power plants and industrial facilities.

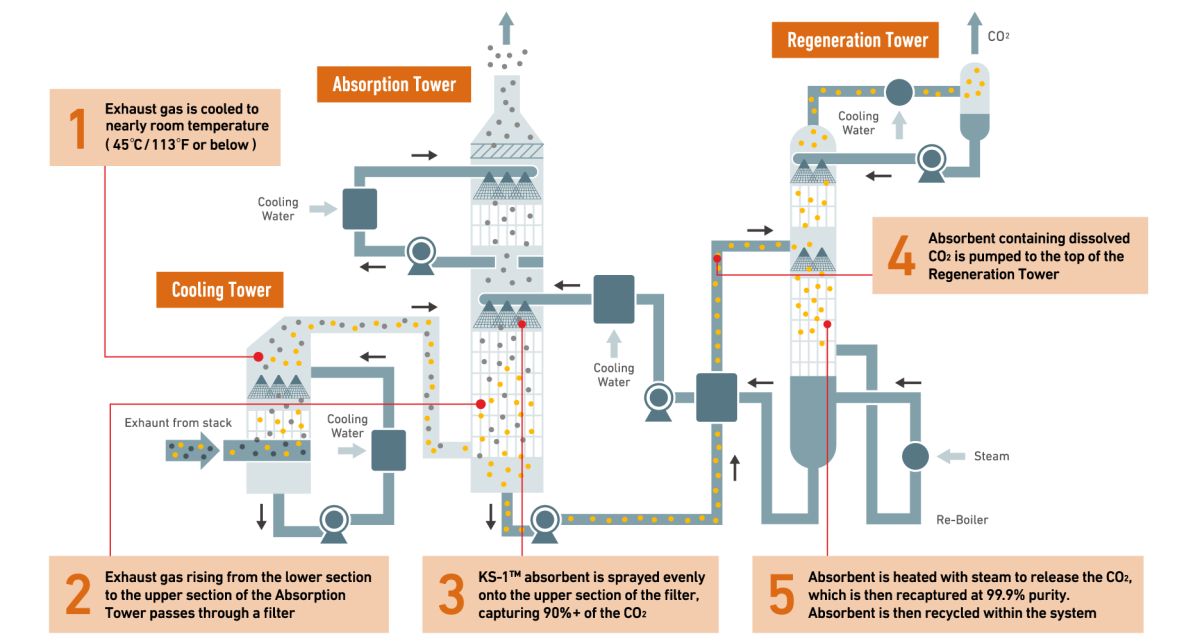

There are two key approaches for removing CO₂ in these settings. Pre-combustion technologies remove CO₂ from fossil fuels before they are burned to generate energy. Post-combustion removes the CO₂ generated by burning fossil fuel or other industrial processes.

While pre-combustion is more efficient as a higher concentration of CO₂ can be released, these technologies typically need to be implemented from the design stage. Post-combustion technologies can be retrofitted to existing facilities and are also able to capture CO₂ from a broader range of industries.

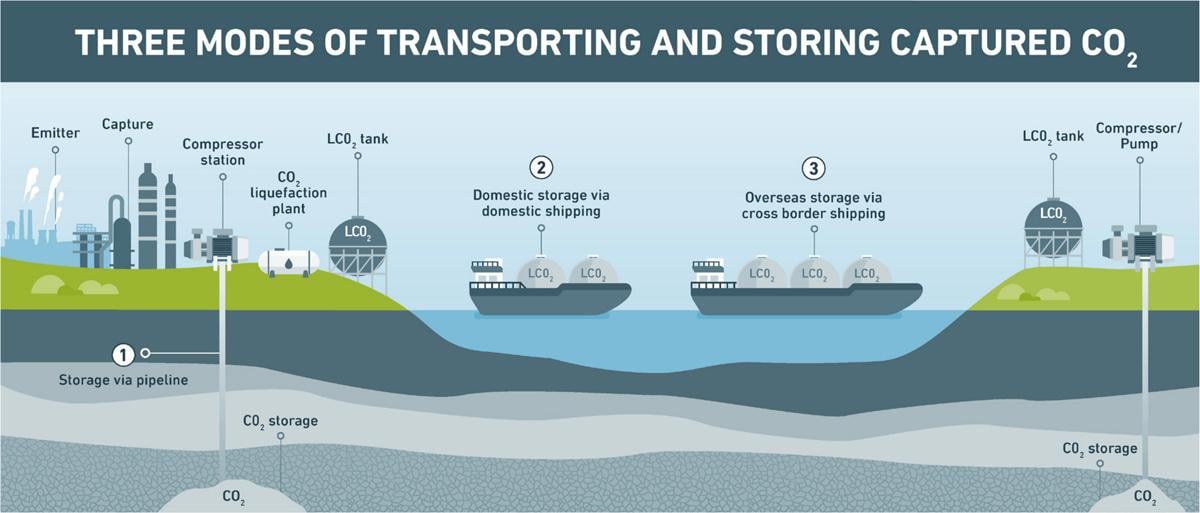

The captured carbon dioxide will be taken by pipeline, ship, rail or road to permanent storage sites such as saline aquifers or depleted oil reservoirs, or used in various industrial applications requiring CO₂.

Read more: CO₂ Capture Technology

Why is CCUS key for the energy transition?

Power generation and ‘hard to abate’ industries such as steel and cement are among the biggest CO₂ emitters. These sectors are expected to decarbonize by either electrifying industrial processes or moving to low-CO₂ fuels such as hydrogen. However, while sectors such as steel and metal making have made considerable progress in their decarbonization, this transition isn’t straightforward. Electrification is difficult where very high temperatures are needed for material conversion. Another challenge is that fossil fuels are often not just a source of energy but a feedstock and a by-product of industrial processes.

Therefore, during their transition and for any residual CO₂ emissions, CCUS will be vital for cleaning up their exhaust fumes. This is because CO₂ capture can remove more than 90% of CO₂ emissions.

Read more: The CCUS value chain

When was CCUS invented, and how widespread is it today?

Capturing carbon dioxide to reduce anthropogenic CO₂ emissions is not a new concept. It was first raised in a scientific paper in 1977, and the first large-scale demonstrations took place in the late 1990s.

Historically, the US has held the highest market share in CCUS due to its extensive use of CO₂ in Enhanced Oil Recovery (EOR). The world’s largest post-combustion CCUS plant to date, situated at the W.A. Parish coal power station southwest of Houston, Texas, began operating in 2016 to provide CO₂ for EOR. This plant adopted MHI's proprietary CO₂ capture technology that it has been developing with the Kansai Electric Power Co., Inc. since 1990.

Yet, globally, CCUS has had a bumpier ride due to vacillating policy support, questions over viability, and public concerns about potential risks. However, with the IEA listing more than 700 CO₂ capture projects across the globe, and Wood Mackenzie predicting accelerated momentum for final investment decisions, CCUS could finally be on a growth trajectory.

Read more: Leading the way on CCUS in the EMEA region

What is direct air capture, and how does it relate to CCUS?

Alongside removing CO₂ from power or industrial plant flue gases to mitigate global warming and climate change, Direct Air Capture (DAC) technologies may be needed to extract CO₂ directly from the air to reduce its impact on our planet.

DAC has been attracting growing interest in recent years, though it is also not a new technology. It was originally developed to capture CO₂ onboard spacecraft and then adapted for use on Earth, generating negative emissions to alleviate existing pollution levels.

Read more: Could Direct Air Capture help us reach net zero?

What is the CO₂ value chain and why is it important?

Building on the current momentum for CCUS will require global cooperation from all stakeholders, from policymakers to equipment manufacturers — and end users.

As a new white paper from Mitsubishi Heavy Industries highlights, key to getting CCUS onto a successful trajectory will be an integrated value chain that seamlessly interconnects all stages between the point of capture to where CO₂ will ultimately be stored or used.

Storage will be easier to realize in countries like the US, with its vast landmass and varied geology like aquifers, old oil wells and salt caverns to sequester CO₂. In other geographies, captured CO₂ must be transported further afield or local CCUS hubs created to put emitters and offtakers closer together. Alongside, new uses of CO₂ beyond EOR must be nurtured.

A seamless value chain will make CCUS projects more attractive to investors, but policy support will continue to be vital. This includes instruments such as carbon pricing but also fostering a culture accepting of ‘green premiums’ to contribute to sustainable, resilient energy systems.

Discover more about the future of CCUS in the MHI whitepaper