Could direct air capture help us to reach net zero?

Extreme heat caused by climate change is fueling wildfires in the tundra and costing lives. At the same time, heavy rainfall is creating catastrophic flooding.

As weather-related devastation becomes more frequent, the world is no longer in a place where carbon dioxide (CO₂) reduction alone will be enough to reverse the ravages of climate change.

According to the Intergovernmental Panel on Climate Change (IPCC), the removal of CO₂ is now a critical part of keeping global warming to within 1.5°C. With global emissions at over 36 gigatonnes a year, the longer the delay in cutting them, the more we are likely to need negative emissions technology like direct air capture (DAC).

But what is direct air capture, and what kind of role could it really play in reaching net zero?

Why we need direct air capture

DAC is one of the only ways to remove CO₂ from the atmosphere using technology, and has a number of benefits. For instance, DAC plants can be sited next to carbon storage or utilization facilities, in a way that allows the CO₂ to then be used for other purposes, such as feedstock. DAC could also be commercialized on a smaller scale in domestic settings, with household capture using a machine similar to a dehumidifier enabling the onward use of CO₂. Gardeners, for instance, may use it to fertilize plants. CO₂ could also be collected for industrial use.

As the International Energy Agency (IEA) notes, DAC can also offset some of the emissions from those sectors that are difficult to decarbonize − like heavy industry and aviation − supporting a faster transition to net zero.

How does direct air capture work?

Direct air capture technology was originally developed for use in space and beneath the waves, because an excess of CO₂ in a submarine or spacecraft could be fatal. It is only in recent years that efforts have been made to expand the technology on a broad commercial scale.

DAC extracts CO₂ directly from the atmosphere, using one of two different technologies.

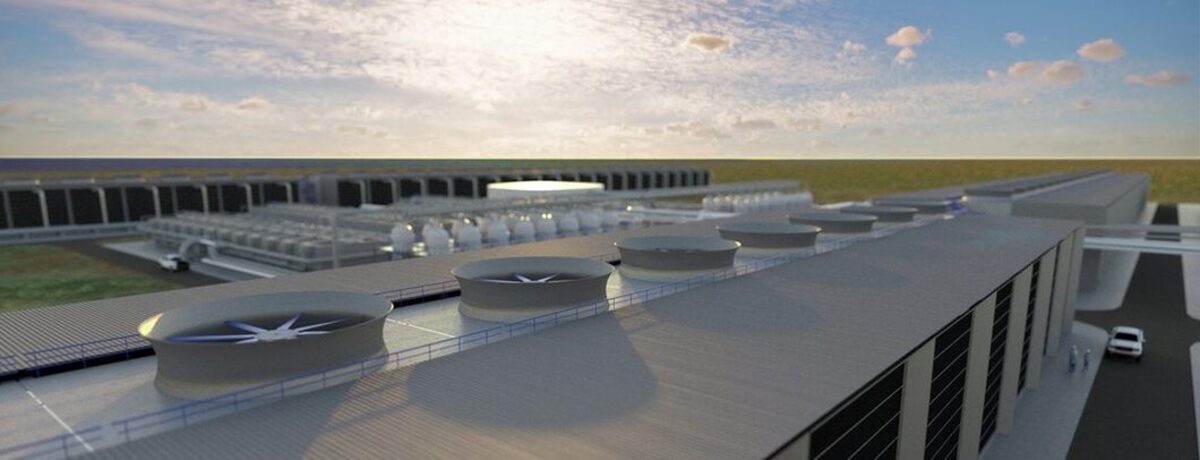

Liquid systems pass air through chemical solutions, removing CO₂ while returning the rest of the air to the environment. This is the approach used by Canadian firm Carbon Engineering, which installs giant fans to suck air into a cooling tower. CO₂ in the air is then bound with a potassium hydroxide solution, trapping the CO₂ in the solution as a carbonate salt.

While direct air capture typically costs between $250-$600 per tonne, the market is moving fast, and Carbon Engineering has estimated that it can capture CO₂ from the atmosphere for less than $100 per tonne. At this price, putting in place DAC to make existing thermal power plants carbon neutral, for example, starts to become viable.

Carbon Engineering recently announced plans for Europe’s first-ever large-scale DAC facility, in Scotland.

Solid direct air capture technology, meanwhile, uses solid sorbent filters, instead of liquid. These filters chemically bind with CO₂. The concentrated CO₂ that is released when the filters are heated can then be stored or used, for instance, in a synthetic fuel.

Swiss company Climeworks is one of the pioneers of this technology, using a modular plant design that could make it easier to scale up DAC, according to a study by Imperial College London. Using this design, Climeworks is aiming to capture 1% of global CO₂ by 2025. Orca, its new plant in Iceland, will combine DAC with underground storage, trapping 4,000 tonnes of CO₂ a year.

How scalable is direct air capture?

Alongside other negative emissions technologies, direct air capture can address distributed emissions – such as those from transport, industry and buildings – that cumulatively account for close to 50% of all emissions.

Even if DAC could help lower the overall cost of CO₂ mitigation, as a process, it is energy-intensive: the Climeworks plant in Switzerland needs around 600 KWh of electricity to capture 1 tonne of CO₂. That is around the same level of energy required to light an average UK home for a year.

There are dangers in over-reliance on technologies such as direct air capture. For example, there is the risk that it may never be deployable at scale due to the energy required; the space needed for large-scale sites; and a massive shift in chemical manufacturing in order to produce enough sorbents. We also need to consider a lifecycle analysis (LCA) of CO₂ emissions from DAC – in other words, any indirect emissions that the technology produces.

Because of these challenges, researchers recommend that it be developed alongside a range of mitigation options.

Finding the right business model to enable DAC to scale enough to capture between 3-10 million tonnes of CO₂ a day – the amount needed to remove between 1-4 gigatonnes of CO₂ from the atmosphere by 2050 – will require innovation and government support, as well as private capital.

But investment into DAC technology is growing: by August 2020, Climeworks had raised $110 million. Carbon Engineering has also received significant funding, including from oil and gas companies like Chevron; while another DAC firm, New York-based Global Thermostat, has signed a deal with ExxonMobil to help it scale.

As more companies put their faith in DAC technology, its position as a central piece of armor in the battle against climate change is growing stronger.

Learn how to tackle CO2 and achieve net zeroDownload MHI Group's free whitepaper.