Leading the way on CCUS in the EMEA region

While it’s important not to view carbon dioxide capture, utilization and storage (CCUS) as a silver-bullet solution to the climate crisis, carbon capture technologies can play a crucial role especially in helping hard-to-abate industries decarbonize their operations and in efforts to reach net zero emissions.

Current global capture capacity needs to increase almost 30-fold by 2030 to put us on course for net zero, according to the International Energy Agency (IEA).

And while new projects are on an upward trajectory across the EMEA region and other parts of the world, realizing the technology's full potential depends on it operating at scale — doing so quickly and collaboratively.

CCUS policy and landscape in EMEA

As one of the world’s largest carbon markets, Europe is home to a growing network of carbon capture initiatives. There were 71 existing or planned projects underway at the end of 2022, which could produce a combined capture capacity of around 80 MtCO₂ per year by 2030. This includes the development of two secure geological storage sites beneath the North Sea: the Porthos project at the Port of Rotterdam in the Netherlands and Northern Lights. They could provide a total storage capacity of 300 Gt, or almost 80 years of current emissions, according to the IEA.

A key tool in the EU’s policy framework is a carbon pricing system on CO₂ emissions within the bloc – the European Union Emissions Trading Scheme (EU ETS). It places a cap on industry emissions, beyond which heavy emitting industries are required to buy emissions allowances. With prices for allowances hovering just below €100 per tonne as of late, and the allocation free allowances being gradually scaled back, the incentives to deploy CCUS in the region are growing.

The value of financial transfers from the EU ETS reached around €751 billion in 2022; funds that can mainly be used to further the EU’s green agenda.

This ETS system is not without its risks, however. While the scheme provides an incentive for companies to find low-carbon alternatives rather than pay a carbon charge, it risks making companies within the bloc less competitive internationally. It could also lead heavy emitters in industries like fuel suppliers to pass additional costs on to customers in the form of higher pump prices.

That said, government incentives and a regulatory framework to help meet climate commitments are an important part of efforts to scale up carbon capture solutions throughout the region.

A funding pot of €1 billion — part of a wider €3 billion fund for low-carbon projects — from the EU’s Innovation Fund has been made available for innovative decarbonization initiatives, including CCUS projects, as part of the REPowerEU Plan.

The policy framework must also encourage sufficient investment in new infrastructure for carbon capture, transportation and secure geological storage.

In response to President Joe Biden’s Inflation Reduction Act (IRA) legislation, which builds on the 45Q tax incentive scheme to offer investors significant tax breaks and subsidies for new capture projects based in the US, the EU is creating its own package of incentives to prevent investments leaving Europe for America.

Hubs and clusters

Across the English Channel from mainland Europe, the UK has pioneered several CCUS hub and cluster projects. These are made up of a group of local CO₂ emitters that use their proximity to share common CCUS infrastructure to reduce emissions.

The Zero Carbon Humber project in the UK’s North East aims to become one of the world’s first net zero industrial regions, for example, combining oil refining, steelmaking, chemical and cement production. Working together, they can unlock CCUS’ local potential by capturing carbon from both natural gas and biomass-fired power generation and hydrogen production, which will be piped to secure storage sites beneath the North Sea.

As part of the Zero Carbon Humber cluster, Mitsubishi Heavy Industries (MHI) is working with Drax to provide carbon capture services to its bioenergy power station near Selby. Bioenergy with carbon capture and storage (BECCS) power plants can generate stable, reliable, baseload power and heat using biomass as a fuel.

The project aims to permanently remove 8Mt of CO₂ per annum from the atmosphere. In doing so Drax Power Station aims to become one of the largest sources of Carbon Dioxide Removals (negative CO₂) in the world.

A feasibility study is also in progress to explore ways of utilizing captured CO₂ from the plant to produce proteins to manufacture sustainable animal feed, helping to promote the circular economy.

Since leaving the EU, the UK has established its own emissions trading scheme (UK ETS), which mirrors the EU ETC “cap and trade” carbon pricing policy in many respects. A limit is set on the total amount of carbon dioxide that can be emitted, which decreases over time so total emissions fall. Once the cap has been exceeded, per-tonne carbon allowances must be purchased at market prices.

The UK has committed to legally binding carbon reduction targets and aims to become net zero by 2050.

To that end, the UK government’s March 2023 budget announced a £20 billion support package to encourage early development carbon capture projects. The package aims to create 50,000 jobs, attract private sector investment and help capture 20-30 million tonnes of CO₂ annually by 2030, as part of wider efforts to support 500,000 new green jobs by 2030.

Responding to the growth in demand and government support for CCUS projects in the UK and across Europe, MHI is increasing its local presence with a rapidly growing dedicated decarbonization team based in London.

Innovation drives progress

In what is essentially still a nascent sector, innovation plays a key role in bringing new CCUS projects online across EMEA.

As a leading innovator of CCUS solutions, MHI has pioneered a number of proprietary technologies aimed at capturing and transporting carbon dioxide from power plants and industrial facilities.

A program of tests conducted at the Technology Centre Mongstad in Norway, led to an evolution of our existing proprietary KS-1 solvent used in MHI’s KM CDR Process, for example.

The new KS-21 amine-based solvent provides greater stability against degradation than previous versions, while reducing volatility, environmental impact and operating costs.

The tests confirmed a carbon capture rate more than 95%, which exceeds the industry standard of around 90%, although the carbon capture rate increased to 99.8% in tests conducted under specific operating conditions.

After absorbing carbon dioxide from flue gases, the CO₂-rich solvent is piped to a regenerator, where steam separates the carbon dioxide, which is more than 99.9%-dry pure. It is then transferred to a compressor ready to be utilized or transported to a secure storage site, with the solvent recycled to begin the process again.

Modular designs, transportation and trade

While heavy industry often prides itself on developing big technologies, big infrastructure and big projects, small can also play an important role.

Alongside the bespoke capture systems built for power stations and large-scale industrial facilities, at MHI we have developed a compact carbon capture system, called “CO₂MPACT”, to reduce costs and shorten manufacturing and installation lead times.

One of the compact CO₂ capture systems that has recently started commercial operation in Japan has the capacity to capture 0.3 tonnes per day (tpd) and is based on a highly versatile standardized design requiring an installation space of just five meters in length and two meters wide.

The small size of the systems will also allow carbon capture technologies to be applied to even wider range of industrial applications, including small utilities.

Building upon this, MHI is expanding its lineup of compact CO₂ capture systems, ranging up to a CO₂ capture capacity of 200 tpd.

Compact CO₂ capture systems will help promote the spread of CCUS solutions across the EMEA region, enabling more industrial emitters to implement carbon capture technology in a more affordable way.

While preventing CO₂ emissions from industry reaching the atmosphere is a vital component of efforts to combat climate change, the story does not end there. Scaling up CCUS adoption and developing a value chain for CCUS across the EMEA region requires new infrastructure to transport, store, track and monitor the captured CO₂.

But investing in new capture projects and infrastructure is not without its risks in an industry that must also build demand for CCUS technology.

That’s why Mitsubishi Shipbuilding is undertaking a conceptual study and construction of a demonstration test ship for the CO₂L-BLUE dedicated liquefied CO₂ carrier, to provide a cost-effective way to meet the projected increase in demand for transporting liquefied CO₂.

While trucks and pipelines can transport captured CO₂ over land or to geological storage close to capture sites, specially-designed marine bulk carriers will be essential for long-distance transportation — either to distant storage sites or to be utilized by industrial offtakers.

This is particularly important for countries and regions that have few suitable geological storage sites, for example. For CCUS technologies to be adopted at scale, industries without access to local storage will need to transport captured CO₂ in bulk to distant storage sites using specially-adapted marine vessels.

The CCUS landscape will continue to evolve, with more CCUS projects and storage sites coming online, greater volumes of captured CO₂ traded to industrial end users, combined with stricter legislative measures such as carbon taxes. This will require greater verification and traceability to track, transport, trade and sequester captured CO₂.

In light of this, MHI is developing the CO₂NNEX Digital Platform together with IBM, to promote the CCUS value chain and increase collaboration between CO₂ emitters and offtakers — in effect linking sellers and buyers. The platform increases transparency and accountability of carbon sources to facilitate trading and storage.

Working in partnership with IBM, the platform implements blockchain technology and Internet of Things (IoT) connectivity in a cloud-based solution that can analyze, record and authenticate volumes of captured, stored and traded CO₂ in real time.

Smart innovations like CO₂NNEX could help create a CCUS value chain by turning captured carbon dioxide into a tradable commodity.

Regional CCUS applications

Innovations like these are already at work supporting regional efforts to reach net zero emissions across many of EMEA’s industries.

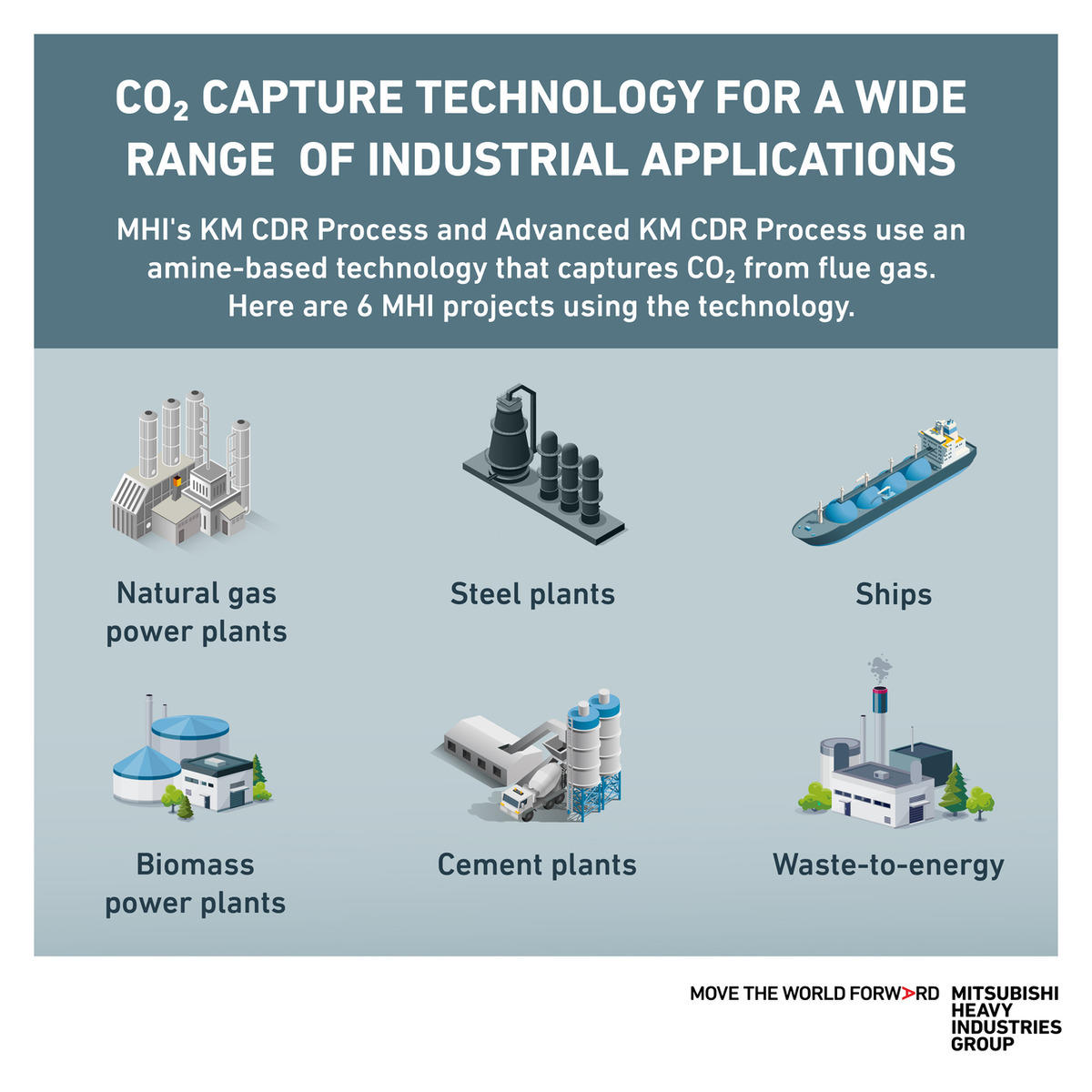

And CCUS solutions can already be applied to many industries, but leading companies like MHI continue to work with different sectors to develop new solutions for applications to various flue gas sources.

We are proud to be part of the UK’s first carbon capture initiative in the cement industry, using MHI’s advanced KM CDR Process and the proprietary KS-21 solvent, for example. This meant producing the preliminary front-end engineering design (pre-FEED) for a carbon capture plant at the Padeswood cement works in Flintshire in Wales, with an annual CO₂ capture capacity of 800,000 tonnes. Captured CO₂ will be transported to a secure storage site in a spent gas field off the country’s North West coast.

In the steel industry, a multi-year trial of the company’s carbon capture technology is underway as part of a collaboration with ArcelorMittal — the world’s leading global steel and mining concern — at its Gent steel plant in Belgium. A feasibility study is being conducted to support progress to full-scale deployment.

Alongside other power-generating projects, our team is supporting commercial-scale carbon capture operations at Peterhead Carbon Capture Power Station in Aberdeenshire, Scotland, with pre-FEED and FEED for its gas turbine combined cycle (GTCC) power plant and carbon capture plant. This first-of-its-kind project in Scotland could capture up to 1.5 million tonnes of CO₂ annually, which would be transported and stored beneath the North Sea.

In the Middle East, MHI is conducting a feasibility study to apply its core carbon capture technologies at Aluminium Bahrain BSC (Alba), an aluminium smelter plant in Bahrain, the largest smelter in the world ex-China. Success here will represent the first commercial application of carbon capture technology in the aluminium sector.

While the number of new projects in development across the EMEA region continues to increase, more is needed to meet climate targets. Policymakers in the EU and other regional powers, together with original equipment manufacturers and private companies across many hard-to-abate sectors, must collaborate to create a framework that encourages investment in new CCUS capacity.

Building on decades of hard-won expertise and development ability, MHI deploys a range of solutions among the CCUS value chain throughout the EMEA region: from advanced carbon capture technologies to long-distance transport.

Innovation, collaboration and expertise are essential components of regional efforts to help EMEA’s energy and industry majors realize their net zero ambitions. That’s why we are continually pushing boundaries to develop new and more effective CCUS solutions.

Discover more about MHI's CCUS activities