A decade of pioneering green steel solutions

Index

The past decade has been one of disruption and breaking new ground for the steel industry. Marked by the adoption of the Paris Agreement in 2015, this period ushered in the twin challenges of digitalizing steelworks and decarbonizing operations to produce green, sustainable steel.

2015 also saw the inception of Primetals Technologies, a Mitsubishi Heavy Industries (MHI) Group company conceived as a one-stop technology shop to support steel’s twin transformation.

As Primetals Technologies celebrates its 10th anniversary, we speak to Yoshiharu Ikeda, CEO of Primetals Technologies, and Dr. Alexander Fleischanderl, Primetals Technologies’ Chief Technology Officer (CTO) and Head of Green Steel, about the sector’s evolution and its green transition.

How has the past decade shaped the steel sector?

Yoshiharu Ikeda: When I look back, what stands out is the determination of policymakers worldwide to limit global warming to between 1.5°C and 2°C. There has been a raft of policy frameworks to support industrial decarbonization. Steelmaking generates 1.9 times more CO2 than actual steel. The global steel industry’s emissions make up about 8% of the total global carbon footprint. It has been Primetals Technologies’ goal from the outset to support the sector with the technologies needed to cut these emissions and make production more sustainable.

Alexander Fleischanderl: I would add that, in addition to the Paris Agreement itself, another trigger for steel’s decarbonization was the EU Green Deal in December 2019. Especially in Europe, this really changed the pace of steelmakers’ net zero strategies. It kicked off an intensive phase of discussing the possible transition pathways and coming to a common understanding between steelmakers, technology providers, policymakers and financing institutions about the way forward. So, for Primetals Technologies, this provided us with a roadmap to follow.

What would you rank as the biggest advances in green steelmaking over this decade?

Alexander Fleischanderl: We’re seeing three distinct phases the industry has been going through. The first phase was optimization; so, improving energy efficiency, yields and circularity — with no major capital investments. In the past two years, we’ve entered what we call the transition phase, electrifying processes wherever possible. Steelmakers are shifting from coal-fueled blast furnaces to electric arc furnaces (EAF) and using steel scrap and hot-briquetted iron (HBI) as feedstock for electric steelmaking. There are also innovative technologies for endless continuous casting and rolling, such as our Arvedi ESP (Endless Strip Production) technology, which skip the traditional approach of cooling and reheating steel slabs between casting and rolling. Again, this brings the carbon direct emissions down to zero and reduces the land footprint as well as costs.

What are the next steps for steel’s green transition?

Yoshiharu Ikeda: The next — and third — phase we are focusing on is transitioning to fully decarbonized steel production methods, such as Primetals Technologies’ hydrogen-based fine-ore reduction — or HYFOR solution. Here, we reduce carbon emissions in the iron ore reduction process by using sustainable hydrogen as the reduction agent instead of coal or natural gas. The industrial-scale demonstration plant that we have started constructing this year in Linz, Austria, jointly with our partners voestalpine and Rio Tinto, is at the heart of this lighthouse project for Primetals Technologies and the whole industry.

Alexander Fleischanderl: What makes HYFOR so unique is that it uses fine iron ore. This eliminates the usual pelletizing and agglomeration steps, which are both energy- and CO2-intensive. Moreover, our tests over the past four years have shown that HYFOR can utilize any type of iron ore, regardless of quality. We can then feed this Direct Reduced Iron (DRI) into a Smelter and — using 100% renewable energy — convert any grade of DRI into hot metal to the same high quality that a traditional blast furnace would produce, but with 90-95% less carbon emissions. Following the final investment decision (FID) in April this year, we’re preparing to start up the hydrogen-based ironmaking demonstration plant in fall 2027 and to deliver a first commercial rollout of the technologies in 2028. Additionally, a key aspect of the transition phase is to provide steel producers with technology that sets them up for a future “green” society. As an example, more and more automobile manufacturers are increasing their production of electrified vehicles. This means that we see an increased demand for harder and thinner flat steel products, which contribute to reducing weight and, consequently, to reduced emissions. To produce these steel products, the latest rolling technologies are required. Our HYPER UC-Mill technology reduces the rolling force by 10% and is geared toward the production of electrical steel and Advanced High-Strength Steels (AHSS).

What needs to happen to speed the uptake and commercialization of green steelmaking over the next decade?

Yoshiharu Ikeda: I can see several major challenges for the decarbonization of steel right now. The first is ensuring that there is a stable supply of hydrogen. Establishing the hydrogen supply chain and reducing hydrogen costs are essential to attracting steel producers and investors. This requires lowering electricity costs by increasing the renewable energy share and enhancing market efficiency.

The second challenge is capturing CO2 from existing blast furnaces and any remaining fossil processes that are hard to decarbonize. Past policy support for CO2 capture technologies was limited. But governments have now recognized that relying on electrification and hydrogen alone isn't enough. We need an approach that is not tied to or favoring any specific technology, tool, or platform. Instead, decisions are made based on what best fits the situation.

Third, the cost of deploying green steel technology and of feedstocks like electricity and hydrogen will add a premium to low-carbon steel. However, steel end-users are less willing to pay extra when they can opt for cheap imports made from fossil fuels instead. Government support will be essential in changing this situation. Measures like the EU Emissions Trading System (EU ETS) and Carbon Border Adjustment Mechanism (CBAM) will be key to levelling the playing field.

How do you see the steel sector evolving over the next decade?

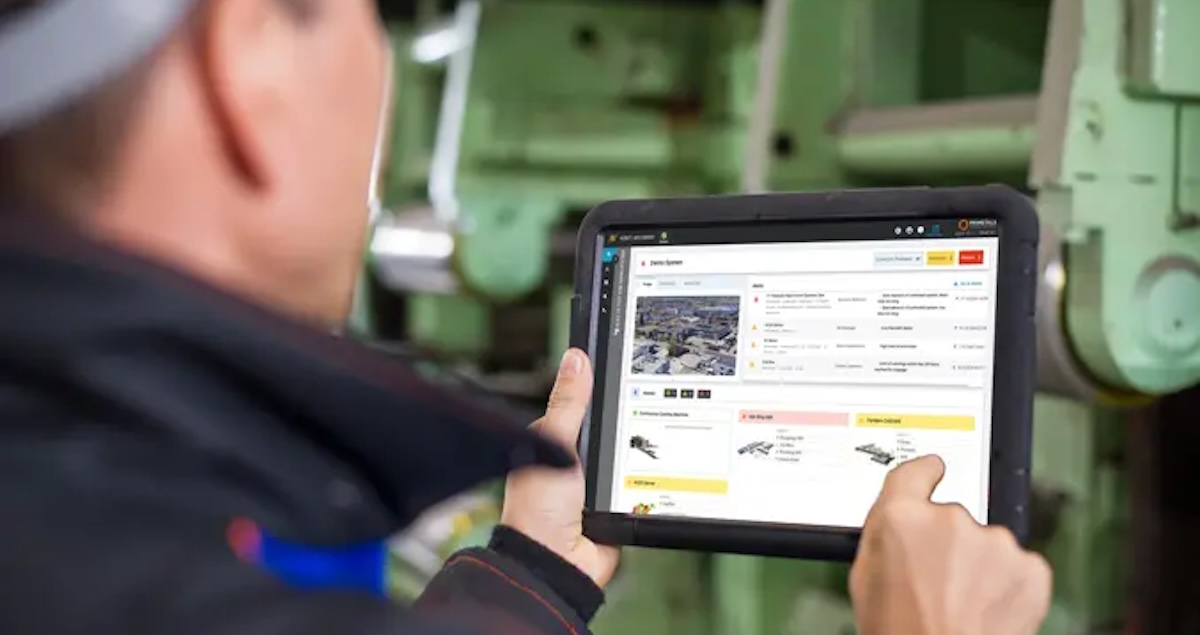

Alexander Fleischanderl: We believe that the transition will progress steadily toward the 2050 net zero target. AI and digital technologies will be vital in this process, speeding plant design, optimizing operations and bridging our industry’s ongoing shortage of skilled staff. Solutions like our Central Operation Cockpit (COC) and Through Process Optimization (TPO) are examples that bring us stepwise closer to autonomous plant operation. These AI-backed technologies support the operators to prioritize anomalies, recommend corrective actions and optimize operational costs. The ultimate target is a very consistent steel product and a reliable plant operation. The COC is a fully digital plant and process twin that is also used as a “flight simulator” to upskill operators and train them to react correctly in emergency situations using a safe offline plant version.

Yoshiharu Ikeda: The steel industry is a vital sector for the global economy. There are no other materials comparable to steel in terms of strength and infinite recycling ability, and demand will continue to grow slowly. But our industry’s expansion must be sustainable. And that comes down to a joint effort by all stakeholders, including policymakers and governments, steel producers and their customers, and the energy companies supplying our electricity. We must all make a concerted effort to achieve carbon neutrality.

Discover more about

Primetals Technologies' focus on the green steel transformation