The race to 65% efficiency

The U.S. is rich in energy supply. We are almost unique in the world in having an abundance of coal, oil and natural gas, along with exceptional wind, solar and hydropower resources in many areas of our country. At the same time, we see an increasing focus on local air quality and global climate change. My company is responding to these emerging challenges and amazing opportunities by enabling the power plant of the future.

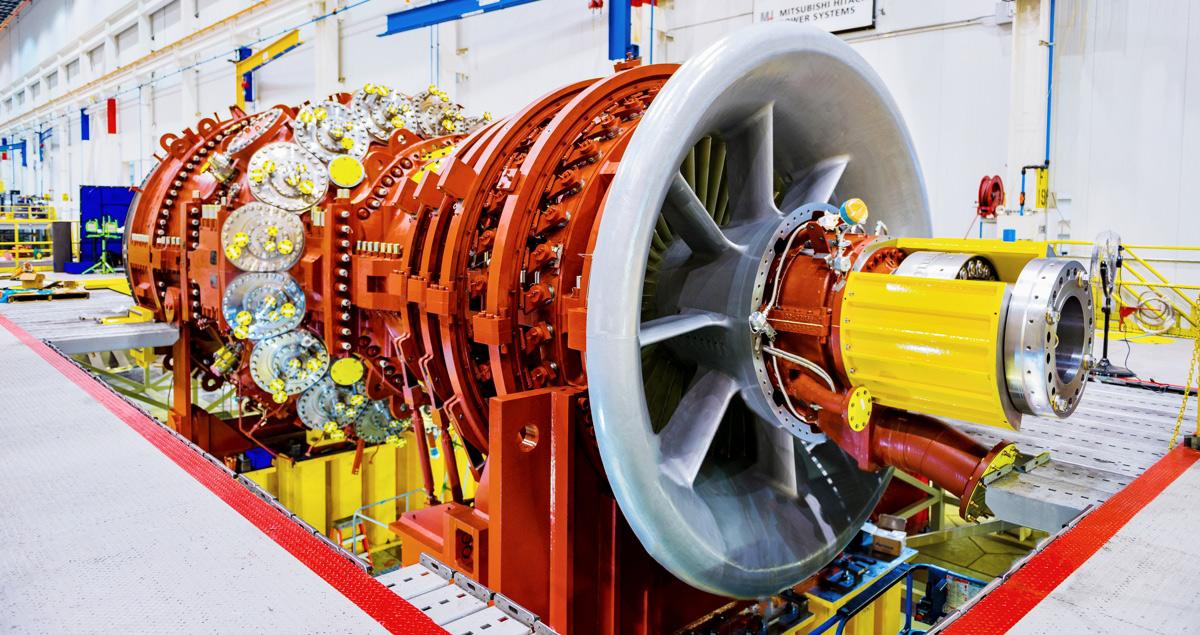

We produce a number of products and services that reduce emissions for new and existing power plants. One of our most exciting products is the combined-cycle gas turbine power plant, which uses jet engine technology combined with steam turbine technology to rotate generators that produce electricity. After decades of R&D, this technology provides the most cost-effective way to generate electricity from natural gas. Our turbines provide fuel efficiency of greater than 63% and produce approximately 65% less carbon dioxide than the coal-fired power plants that they often replace. While that's great news, we are never complacent and constantly work toward the next generation of efficiency.

Race to 65% efficiency

We already offer the world’s largest and most efficient gas turbine, but on any given day we have hundreds of mechanical design engineers, materials scientists, manufacturing experts, aerodynamicists, and supply-chain specialists at work to improve our turbines. We split these experts up into teams and hand them an assignment – a problem to solve. The teams consist of 6 to 8 cross-functional experts who spin off from the larger group to innovate independently. They return to present ideas in our war room where some ideas are put to rest and other ideas move to the demonstration phase. It takes these teams several years to turn their ideas into reliable products, in part because we require long-term reliability testing of our products whereas some of our competitors do not.

We have an international group of design experts – from Tokyo to Orlando. They’re searching for ground-breaking new technologies or even the slightest adjustment, which can improve output and reduce environmental impact. If we can, for example, improve fuel efficiency from 63 to 65 percent – moving the needle by just two percentage points – it can make a huge difference in three important ways:

• The most obvious difference is fuel savings. Two points of efficiency improvement over the 30 year life of our newest air-cooled J-series gas turbine can save a U.S. customer an estimated $50 million in fuel cost. To put that in perspective, that dollar savings is similar to the cost of one of our gas turbines. In a country with higher fuel costs, the savings could be more than $200 million over the life of the power plant.

• The second benefit is emissions reduction. For example, the annual carbon dioxide emissions reduction from a two-point efficiency improvement is the equivalent of taking 10,000 cars off the road for a year.

• Finally, highly efficient power plants get more operating hours, because they’re the last power plant to be shut down when electrical demand is low. This means our power plants generate more revenue for our customers.

Getting from here to there – learning from the Egyptians

One of the most challenging components in our product is called a turbine blade. Each blade rotates 3,600 times per minute, and is simultaneously hit by a 3000 degree Fahrenheit gas mixture that's moving at nearly the speed of sound and is pressurized to over 20 times atmospheric pressure. We go to these extreme temperatures and pressures because the hotter and higher we go, the more power we can generate for a given amount of fuel. To do this, we combine state-of-the-art technology with an age-old technique called lost-wax investment casting.

The earliest known “lost-wax” castings date from the early dynasties of Egypt, nearly 7,000 years ago, when metal was poured into “investments” of fired clay that had been shaped with the help of wax that was melted, or “lost.” Then, sometime between 4,000 and 3,000 B.C., bronze was discovered and used in investment castings. Thus began the era known as the Bronze Age.

To make our most advanced turbine components, we use a modern-day version of this ancient Egyptian technology. Today we use supercomputers to design our castings and the internal passageways that are used to cool them during service. We also use some of the world’s most advanced materials science to develop specialized alloys and coatings that can tolerate ever higher temperatures and stresses.

Energy at the nexus of our global challenges – natural gas and renewables

What excites me every day is that the impact we’re having is much bigger than a couple percentage points of improved efficiency. Our natural gas power plants are more flexible than ever, allowing them to quickly add or subtract power when variable power sources like wind and solar are present. We call wind and solar “intermittent” power sources, and with more and more of these intermittent power sources being added to the electrical grid, the flexible operation of our gas turbines is a key enabler. If we want to continue to add more renewable power to our grid, flexible natural gas will also be necessary – at least until next-generation energy storage technologies become more affordable and scalable (we’re working on these too).

And this combination of highly efficient and flexible natural gas along with renewables is having an impact. In recent years, the United States has been retiring older inefficient coal power plants and replacing them with a combination of combined-cycle gas turbines and intermittent renewables. The result is that we are rapidly decarbonizing the US electrical grid and also improving local air quality. And further good news is that with natural gas and renewables both becoming much less expensive in recent years, we’re also reducing the cost of electricity while we decarbonize.

Energy is a complex issue. While many good people have been convinced that anything related to fossil fuel is bad, I think the evidence of the past decade is very clear that natural gas power generation in combination with renewables is creating a cleaner US power grid that enables greater prosperity. In the next decade, we have huge challenges that need to be met and I know that our company will continue to play an important role in moving the world forward.