The Q&A: Innovating the future of metal making

Index

To many, steel making epitomizes the First Industrial Revolution. Yet, it also spearheads the Fourth Industrial Revolution, rapidly transforming its operations through digitalization, automation and decarbonization.

As Global Head of Technology & Innovation for Cold Mills, Processing Lines and Digital Transformation for Primetals Technologies, Dr Konrad Krimpelstätter is at the very heart of this evolution.

Based in Hiroshima, Japan, he leads a team that helps steel and metal producers implement the technologies needed to reinvent themselves for a new age.

What does a typical day at work look like for you?

A good day starts with an espresso, exercise and meditation. When I’m in Hiroshima, I always cycle to work. I start my day in the office by checking emails before preparing the day’s meetings. My afternoons are busy with meetings across Japan, Europe and the US, sometimes extending into the evening due to time zone differences.

What is your favorite aspect of your job?

Creating and innovating with my team!

I'm always thinking about how we can improve processes and products. If an idea crops up at night, this quickly gets me out of bed. Innovating is what drives me.

Our innovation process starts with a deep understanding of our customers' issues. Based on this, we create a technology prototype that addresses their challenges. We then test and refine this prototype in our lab before moving to the customer site for joint testing and, finally, deployment.

How does your work help move the world forward?

The innovative technologies we develop will change how metals are made in the future. My team aims to develop technology that can produce high-quality steel and aluminum energy-efficiently and cost-effectively. This will enable manufacturers to create more environmentally friendly yet affordable products that improve people’s lives.

What is the most challenging aspect of your role?

It's maintaining the balance between what’s technologically possible and the benefit to our customers. Coming up with technological novelties — while exciting for us as a team — is simply not enough. Our solutions have to be pragmatic and answer to a strong business case.

What recent project are you most proud of contributing to and why?

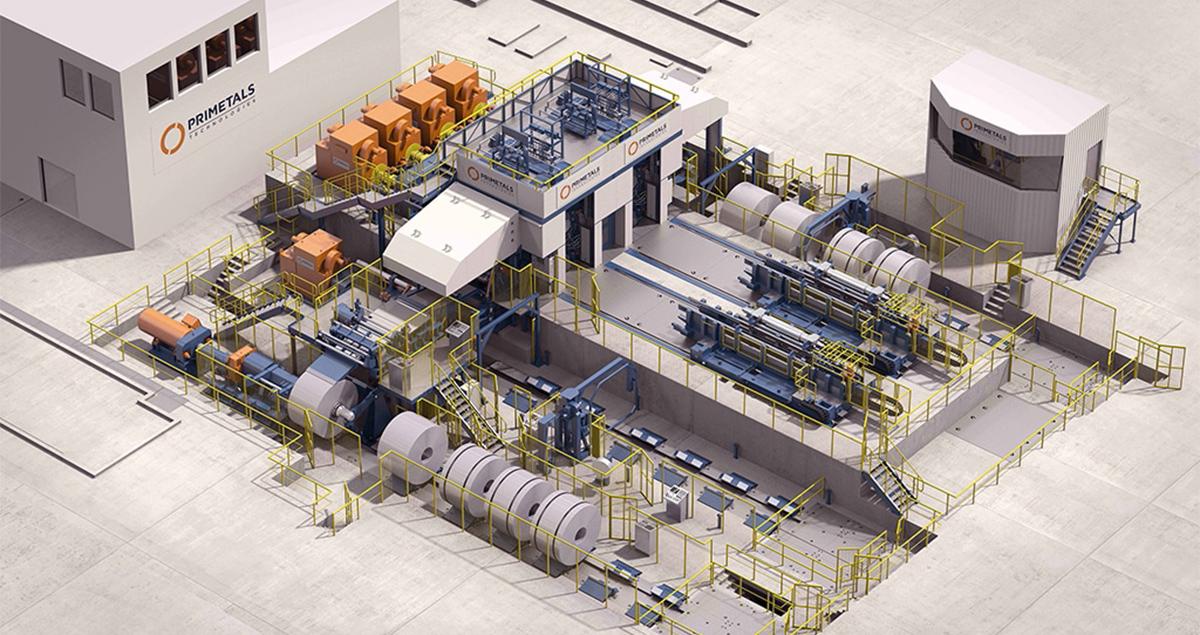

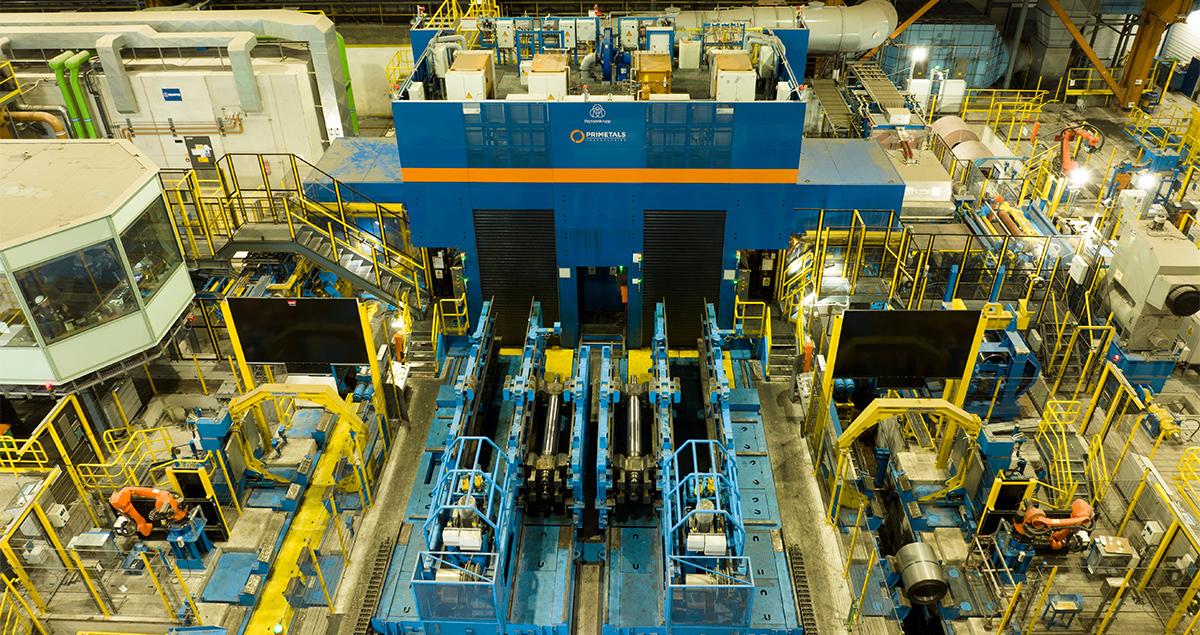

There are so many! However, we recently received the MHI “Best Innovation Award 2024” for a new cold-rolling mill that produces electrical steel sheets. These sheets are in high demand in the automotive sector for the production of electric vehicles. The project saw technology innovation teams from Primetals Technologies’ sites in Austria, Japan and Germany working together over several years.

What’s the most valuable lesson you have learned in your career?

The technology landscape constantly evolves. We must strive to continuously learn and understand new technologies to address emerging challenges and seize market opportunities. For my team and me, lifelong learning is not just a buzzword.

Where do you see the world in 2050?

I envision a world where new technologies are seamlessly integrated into every aspect of life. Advances in artificial intelligence, quantum computing, autonomous e-mobility, renewable energy and biotechnology will transform industries and improve the quality of life around the globe. This includes decarbonization, which will have progressed significantly by 2050. Green steel will dominate the markets, although the transformation may not yet be complete in all parts of the sector.

Primetals Technologies is a part of MHI Group and is providing metals producers with cutting edge, tailor-made technologies, solutions, and services. MHI Group is committed to working together with our customers, partners, and communities across the globe to make the world a better place.