Difference engine - The little engine that could

Index

Downsizing to a car with a smaller engine is being made easier by the latest turbochargers. They can transform a standard four-cylinder engine into a much more powerful motor.

Frugal four-cylinder engines used to be found only in the cheapest cars. But today they are being fitted to even luxury models. What has made them more acceptable indeed, desirable is the development of advanced turbochargers that cram more air than normal into the fixed volume of their cylinders, allowing the engines to burn proportionally more fuel. The result is a compact unit that punches way above its weight in terms of power and torque, a turning force which makes that power available at lower revs. These engines also provide better fuel economy and emit less pollution.

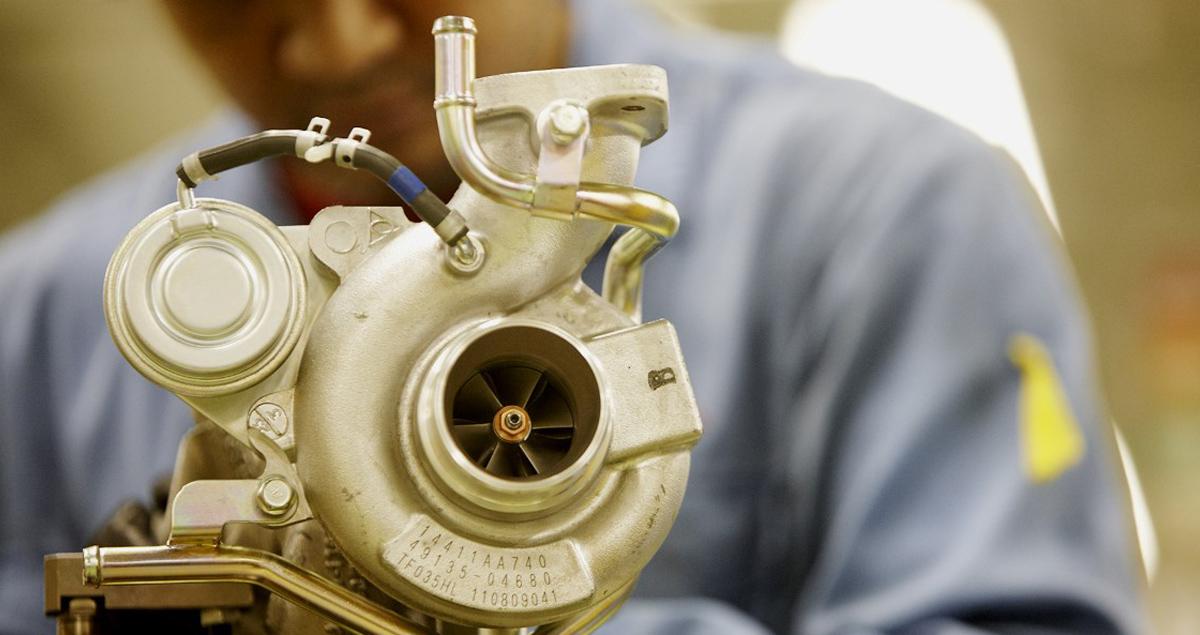

A turbocharger works by tapping the hot exhaust( gas from the engine to spin a small turbine which, in turn, drives an equally small air compressor. For higher performance, an intercooler is sometimes placed between the compressor and the engine’s inlet manifold. This lowers the temperature of the compressed air and raises its density still further. In general, a turbocharged 1.8-litre four-cylinder petrol engine can deliver the power and torque of a naturally aspirated 3-litre six-cylinder unit. By the same token, a turbocharged V6 can be more than a match for a conventional V8.

Turbochargers are not to be confused with superchargers, made famous by the 4.5-litre Blower Bentleys of the 1920s. While they serve broadly the same purpose to squeeze more air into an engine they function differently. A supercharger does not rely on an exhaust-driven turbine but is driven directly by the engine. Superchargers are better in one respect: they do not suffer from “turbo lag” (the time taken for a turbocharger to spool up to speed). The disadvantage is that a supercharger robs the engine of power and, thermodynamically, it is nowhere near as efficient.

Carmakers started to take turbocharging more seriously in 2010, after the American government announced that its CAFE (corporate average fuel economy) target would rise to 35.5 miles per US gallon (6.63 liters/100km) by the 2016 model year. Turbocharged four-cylinder engines typically use 15% less fuel than larger, naturally aspirated, motors of comparable output. Also, with an abundant supply of oxygen to support combustion, the mixture in the cylinders gets burned more thoroughly. The result is a cleaner exhaust all around.

In Europe, where half of all cars and light trucks sold are diesel models, the benefits of turbocharging are well understood. Because diesels ignite their fuel using the heat of compression (rather than spark plugs), they need much higher compression ratios to function. To cope with the greater internal pressure, a diesel’s engine block and cylinder head, as well as all its reciprocating and rotating parts, are made much stronger, and thus are heavier.

Unfortunately, heavy rotating masses do not like being spun rapidly. As a result, diesels tend to operate in a lower, more narrow band of engine speeds. And because they spin relatively slowly, they never get enough air needed to fill the cylinders properly during intake strokes, which is why diesel engines have long used turbochargers to overcome their inherent shortness of breath.

The modern turbocharged petrol engine owes much to its diesel equivalent. But there are significant differences that require design changes. For instance, petrol is more volatile than diesel igniting faster, burning hotter and requiring a lower air/fuel ratio. Petrol engines are also expected to operate over a much wider range of crank speeds, and to respond much more rapidly when called upon by the driver to do so. If turbo lag is longer than a few seconds, the vehicle can be tricky to drive with nothing happening initially, and then the boost suddenly arriving with a wallop.

The reverse is also true. If the turbocharger does not come off boost quickly enough when the driver lifts his foot from the accelerator pedal which causes the throttle to shut off the air flow to the engine pressure waves can surge back to the turbocharger and damage the compressor. To prevent that a “blow-off” valve, which dumps surplus compressed air into the atmosphere, is fitted between the turbocharger and the inlet manifold.

On the exhaust side, a “wastegate” regulates the turbocharger’s output by bleeding off some of the hot exhaust gas so that it bypasses the turbine. This makes it possible to match the amount of energy the turbine receives to the amount the compressor needs, so only as much boost is produced as is required. With their more sedentary nature, diesels avoid much of this complexity.

Numerous other tricks have been tried to make turbochargers more responsive. Obviously, the smaller and lighter the rotating parts in a turbocharger are, the faster it can respond to changes in the throttle setting. Unfortunately, small turbochargers quickly run out of puff. Bigger ones produce all the boost required, but are slow to spool up to speed. A number of hybrid designs have emerged that combine the best of both worlds.

Two are better than one

The most popular type today is the “twin-scroll” turbocharger. This works like a pair of turbochargers connected in parallel, one for each of two separate exhaust manifolds. However, while using a pair of turbochargers reduces turbo lag, it doubles the cost and complexity of the installation. The twin-scroll design gets around this by having two exhaust-gas inlets and two nozzles feeding a single turbocharger. One nozzle injects exhaust gas at a steeper angle to the turbine blades, for quick response, while the other injects the exhaust gas at a shallower angle, for peak performance.

Having two exhaust manifolds on a four-cylinder engine adds, of course, to the cost. But by pairing cylinders so their power strokes do not interfere with one another, the two exhaust streams can be injected into separate spirals in the turbocharger, causing it to spin more smoothly. Apart from making the turbine more efficient, this helps to improve the scavenging of burned gases from the cylinders, lowers the exhaust temperature (and thus emissions of nitrogen oxides) and reduces the turbo lag still further. Small turbocharged engines mean that far from fearing the deprivations of downsizing, motorists could be pleasantly surprised.