Progress in thermal powers cleaner energy mix

Renewables may win most of the headlines as the future of our energy supply, but there is another arena where the battle for cleaning the environment is taking place. And, for the time being at least, it might be even more important.

Nowadays the burning of fossil fuels is often decried as an anathema, yet the reality is that natural gas, coal and oil generate more than two-thirds of the world’s electricity supply, according to the International Energy Agency (IEA). While the share of renewables is quickly growing, the agency’s outlook shows that it is unlikely to become the dominant energy source in the next two decades or so.

What this means is that for the foreseeable future, to make the greatest impact in reducing our planet’s carbon footprint, we must employ as much effort in upgrading current thermal power facilities to low-emissions, high-efficiency technology as we put into solar and other renewables.

The world needs energy solutions that are affordable, sustainable, and clean, according to specialist, Mitsubishi Hitachi Power System (MHPS). In Asia alone, about $11 trillion is expected to be spent on new power generation equipment through 2030, with investment likely to be spread across different energy sources.

“Each energy source needs to be pushing the boundaries in terms of innovation to benefit the environment,” Kenji Ando, the President and CEO of MHPS, said in a recent interview.

Fossils Go to Work for the Environment

In this sense, the advent of new innovations in thermal power, such as the latest combined-cycle gas turbines, should be seen as much a victory for the environment as breakthroughs in photovoltaic panels or in wind turbine blades.

The new J-Series gas turbines, from MHPS, each one able to supply electricity to about 700,000 homes, may be less immediately known to the regular consumer, but their 550-metric-ton hulk cuts CO2 emissions by about nearly 70% compared to conventional coal-fired power plants, and their generation efficiency is some 20% higher.

You may ask why measuring new gas turbines against coal plants even matters in a world in which renewables accounted for more than half of all new electrical capacity installations last year?

Because, despite recent moves towards cleaner alternatives, we still use a lot of coal.

Coal-fired power plants account for about 62% of China’s installed electricity capacity and 60% of India’s, the two most populated nations. Japan relies on coal for a third of its energy needs, while the world’s largest economy, the U.S., is projected to continue relying on both coal and other fossil fuels for 59% of its electricity needs at least through the middle of next decade.

Shifting much of this global coal capacity to natural gas, bringing in combined cycle technologies that also utilize steam to increase output and efficiency, and adding new air-quality control systems, such as the flue gas treatment process pioneered by MHPS, among other innovations, could make a massive difference to our CO2 emissions.

The CO2 emissions per unit of electricity of MHPS’s J-Series combined-cycle (cc) gas turbines are nearly 70% lower than the coal-fired power plants they often replace, according to the company. This is despite J-Series being the largest operating units in the world at 470 MW and 680 MW (cc) output.

It is possible to halve the world’s CO2 emissions by 2040, providing we enact appropriate policies and introduce innovative technologies specific to fossil-fuel combustion, the IEA said in a 2016 global energy outlook.

Good for the Environment Means Good for Business

Given the heightening awareness of environmental issues globally, and at the same time the need to continue investing in new power capacity, doubling-up on innovation in the energy sector makes good social and business sense. Which is why two Japanese engineering giants, Mitsubishi Heavy Industries and Hitachi, decided to pool their resources in thermal power equipment, and formed a new company MHPS, in 2014.

The venture combined Mitsubishi Heavy Industries’ and Hitachi’s expertise in thermal power generation technology including advanced-class gas turbines, steam turbines, boilers, and air quality control systems, helping the new entity establish itself among the world’s top three suppliers of those products.

The global gas turbines market for the power industry will likely have a compound annual growth rate of 2.44% during the period 2017-2021 mainly due to the race to lower carbon emissions, according to a recent outlook produced by London-based market research firm Technavio.

For MHPS, in particular, this bodes new opportunities to expand outside its strong presence in Asia and North America, to regions such as the Middle East, Africa, and Latin America.

“In our energy business, we see there is short-term demand for clean thermal power solutions—particularly for clean gas technologies—that emit significantly less CO2 and other substances,” Mitsubishi Heavy Industries’ President Shunichi Miyanaga said in a recent interview.

One of these solutions is the aforementioned J-Series combined-cycle gas turbines, which will deliver a world-leading heat efficiency ratio of over 64% (each 1% increase is equal to taking 13,000 cars off the road). This is achieved by allowing the turbine, which takes in fresh air, compresses it and mixes the result with fuel, to operate at a class of 1,600°C, the point at which steel glows bright red.

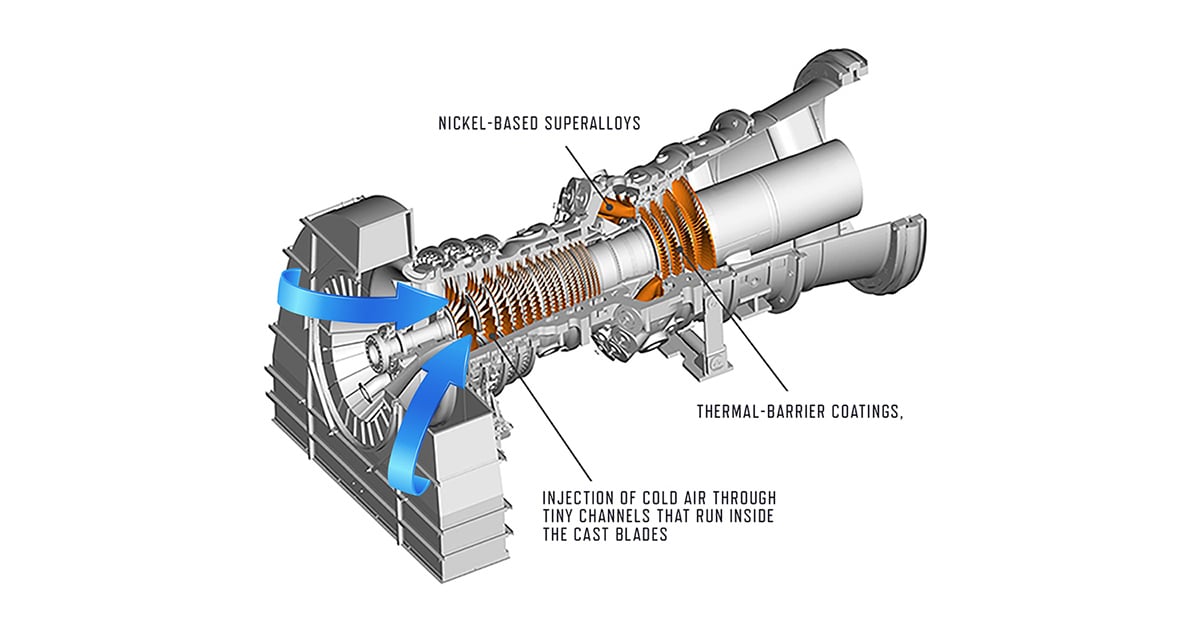

To keep the turbine from melting, a range of complex innovations are relied upon, from the use of nickel-based superalloys, to special thermal-barrier coatings, to the injection of cold air through tiny channels that run inside the cast blades. Such steps helped to push the temperature limit at the inlet of the gas turbine from around 900°C three decades ago to 1,600°C today.

Turning Up the Heat for the Next Challenge

Each further improvement requires time and investment. MHPS has already set its sights on rolling out a 1,700°C gas turbine within a decade.

“To solve global warming and energy problems all at the same time, it is key that we reduce carbon emissions from energy sources and increase efficiency,” MHPS engineers wrote in a recent research paper. While new sources such as renewables must be brought in an economical and rational way, as a race, we urgently need to deploy the most efficient thermal power generation systems to enable us to minimize the use of fossil fuels.”

Among other solutions in the thermal power space, MHPS is promoting the use of Integrated coal Gasification Combined Cycle systems, a next-generation technology that turns coal from a solid into a gas before it enters the combined-cycle gas turbine. Operated on a large-scale, this technology significantly cuts CO2 emissions while boosting power generation efficiency by approximately 20%, according to MHPS calculations. This next-generation technology is already fully deployable, with MHPS leading the process of installing it at plants around the world.

As of this year, MHPS introduced an improved blend of Artificial Intelligence and Internet of Things technologies in the form of a digital platform that enables clients and MHPS’s own engineers to monitor machinery and perform analytics to determine best performance. Called “MHPS-TOMONI”, which means “together with,” the platform is structured so that both the manufacturer and user of the equipment are collaborating towards improving the equipment’s operational performance.

“We are helping customers to detect anomalies and prevent malfunctions in advance, increasing plant operating hours and plant lifespan. We are also helping to facilitate remote and even autonomous operations of power plants,” MHPS President and CEO Mr. Ando said.

After all, what is good for the planet as a whole, is also good for the power generation industry and the customer, the executive notes.

“We take a very long-term view, pursuing sustainable growth that benefits society while ensuring that our products and innovations match both customers’ and society’s needs,” Mr. Ando said.

Learn more about the latest innovations in thermal power generation technology and solutions at Mitsubishi Hitachi Power Systems.