Print me a home

Additive manufacturing scales up

Among the many construction sites in the growing metropolis that is modern Dubai, there is one with an unusual sense of destiny. The building that will emerge is the emirate’s Museum of the Future, due to open in 2018. And, in keeping with the futuristic theme, parts of the structure will be constructed in a novel way: with a 3d printer.

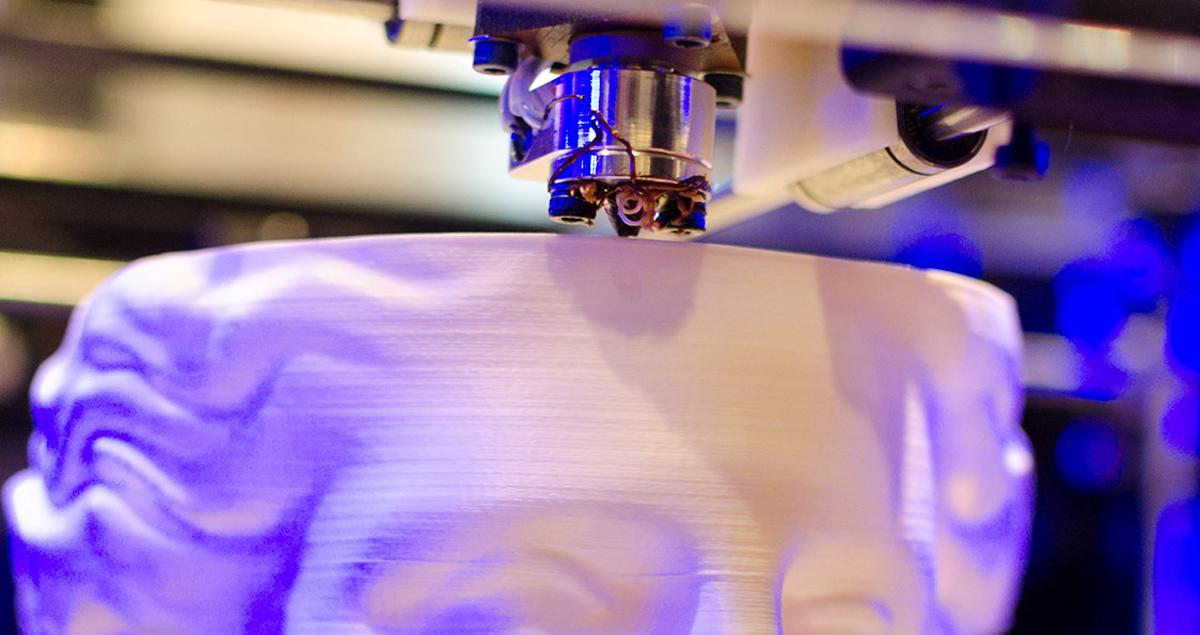

Making things with a 3d printer is fast becoming commonplace. Millions of false teeth are now made every year with the various additive-manufacturing processes employed by 3d printers. Jewellery, countless plastic parts and even components for jet engines are also being printed. Now it is the turn of buildings, as giant 3d printers begin to produce much bigger structures.

The printers usually consist of a large gantry that supports a sort of scaled-up, robotically controlled print head that extrudes a mixture of cement and other materials. A bit like icing a cake, it adds successive layers one on top of the other to form the required shape. This allows sections of a building to be printed in a factory and then assembled on site, or the entire building to be printed in situ.

Foreign and local contractors used a combination of both techniques to print the Dubai museum’s curvaceous office buildings, which are already in use. The rest of the building will be put together using both conventional construction methods and 3d printing. But more is coming. Dubai has now set itself an ambitious target to have 25% of new buildings produced with 3d printers by 2030, says Noah Raford of the Dubai Future Foundation, a government agency. This, he says, will speed up building work and reduce labour and materials costs.

A variety of groups around the world are working on different ways to print buildings. Winsun, a Chinese company, has produced a number of structures, ranging from a small apartment block to public toilets, by printing in concrete, artificial stone and other materials. Skidmore, Owings & Merrill, an international firm of architects, is working with the Oak Ridge National Laboratory in Tennessee on 3d printing low-energy buildings. There are also plans afoot in Amsterdam to print a traditional-looking canal house to be used as an exhibition centre.

An Italian group called WASP has put together a 12-metre-tall 3d printer to construct an entire village in Massa Lombarda, east of Bologna. The idea is that the village will form a technology centre that will showcase how 3d-printing technologies could be used to make low-cost buildings using sustainable materials. WASP is working on a number of ideas, including using the ancient building material adobe, which is made from earth mixed with organic materials. In this case a concoction of clay and straw is pushed out by the printer. WASP reckons two men could use the same method with one machine to print, quickly and cheaply, basic but comfortable shelters. If so a mixture of new and old technologies could help to deal with the fallout from some of the world’s perennial wars and natural disasters.