Meet manufacturing's 'new-collar' workers

White-collar workers use their heads, blue-collar workers use their hands. Although this simplistic division of the workforce was first used in the 1940s, the notion of manufacturing workers as the ones getting their hands dirty stretches right back to the industrial revolution. Even the Latin origins of the word manufacturing - manu factus - made by hand - refers to the physical nature of the work. And it was the dirt and soot associated with assembly lines and machine rooms that made blue shirts more practical than white. However, while collar color once made sense as a neat division of the workforce, it is a concept now hopelessly out of date. Modern manufacturing no longer thinks in terms of white or blue collar - the workers it needs now are “new-collar”.

Blue becomes new

To understand why, you need look no further than Takashi Yoshida, who makes turbine rotors for Mitsubishi Hitachi Power Systems, a joint venture of Mitsubishi Heavy Industries and Hitachi. Takashi has been making rotors for nuclear and thermal power plants for more than a quarter of a century. As a lathe operator, he would classically be regarded as a blue-collar worker. Yet his work requires levels of accuracy and skill that would challenge even a brain surgeon. Rotors must be manufactured to within 5 microns of the required size - that's 5 thousandths of a millimeter. Takashi is a perfect example of the highly skilled professional that modern manufacturing increasingly depends on. Neither white-collar nor blue-collar - they are the new-collar workforce.

Transformation and growth

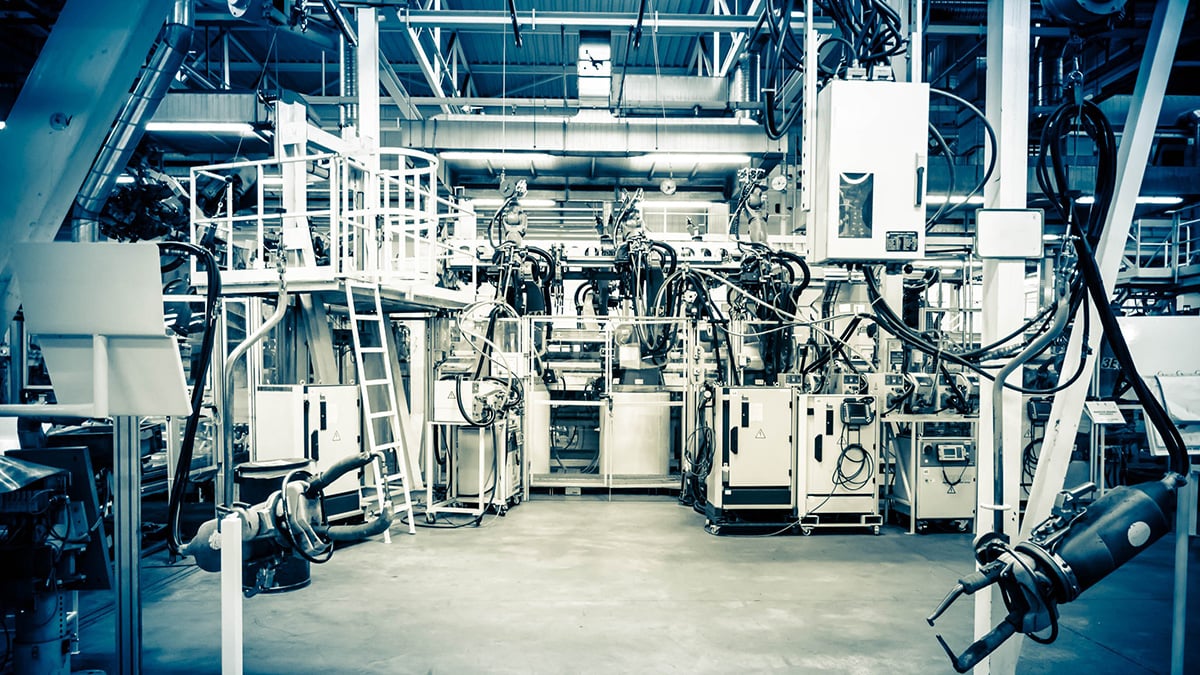

Technology and globalization have transformed manufacturing. Traditional assembly jobs that required little skill or education have been automated as robots and heavy machinery take on the most repetitive and labour-intensive work. The notion that automation will create, rather than eliminate, production jobs seems counterintuitive. Ever since the spinning jenny began replacing weavers, people have worried that machines meant an ever-diminishing number of jobs. But someone has to build those increasingly automated machines, supply the parts for them and constantly improve them. And manufacturing has an extraordinary ability to keep reinventing itself to meet the world's ever-growing appetite for more and better products. Even mature industries like steel are carving out high-tech niches - hundreds of different compositions of the metal designed for an ever-growing number of new products. Which is why employment opportunities in manufacturing are actually growing. In 2017, worldwide manufacturing business conditions showed the largest improvement for more than five years with producers commonly reporting the need to expand capacity in line with rising demand. Attracting more talent is becoming one of the top priorities for the manufacturing sector. Some of the most sought after professionals are highly skilled machinists and craft workers.

New collar, new image

There is a mistaken belief that manufacturing, as a sector, is in decline and, as a result, people may be quick to pass over it as a career option. There is also the challenge of moving on from the old image of a white-collar/blue-collar divide. Not only are huge swaths of manufacturing thriving, but in many factories you would be hard pressed to tell who is working on the 'shop floor' and who is the plant manager. In the 21st century manufacturing plant, everyone is solving problems, everyone is highly skilled. Everyone, in short, is new-collar.

One CEO who has been outspoken on the subject is IBM CEO Ginni Rometty, who has been calling for government and business leaders not to think in terms of white-collar or blue-collar jobs, but new-collar jobs instead. IBM plans to hire 25,000 new-collar employees by 2020. Rometty said she believed that these were jobs that may not require a traditional college degree. New-collar workers may have degrees or they may have gained the necessary skills through vocational training.

Skilling up

It is vital that the new-collar worker concept is not just one associated with the tech industry. Manufacturing already has significant skills shortages. The baby-boomer generation make up around 20% of the current workforce and they are fast approaching retirement. This will increase the need for skilled workers even more.

To address this, young people need to understand the opportunities manufacturing offers and companies need to find new ways to ensure the necessary skills are being taught to prepare people for industry. That new-collar jobs are safer, more intellectually demanding and better paid than the blue-collar jobs that came before them should make a career in modern manufacturing more appealing than ever.

Digital thinking

Innovation, new technology and automation will continue to transform manufacturing - it is a sector forever on the move.

The current period has been called the Fourth Industrial Revolution. The First Industrial Revolution used water and steam power to mechanize production. The Second used electric power to create mass production. The Third used electronics and information technology to automate production. Now a Fourth Industrial Revolution is building on the Third, the digital revolution that has been occurring since the middle of the last century. It is characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.

This means that while established jobs may change, new ones are always emerging. They are there for those willing to acquire the skills and knowledge needed. The opportunities are there to be harnessed. That's why the future really does belong to the new-collar worker.