Graphene filters change the economics of clean water

New approaches to filtration and extracting moisture from air promise to alleviate the world’s looming water scarcity crisis.

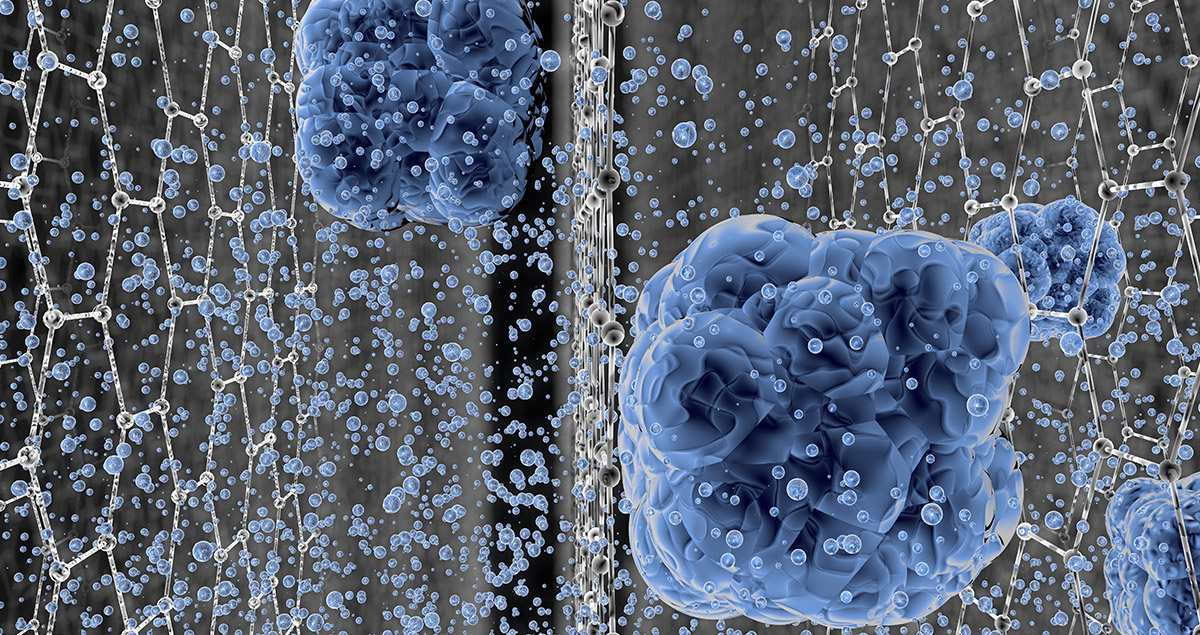

Filtration is being transformed by thin sheets of graphene, a carbon-based material invented in 2004 at Manchester University. Rahul Raveendran Nair, the university’s professor of materials physics, says graphene has the potential to deliver large quantities of clean water via desalination and the removal of pollutants.

Meanwhile, improved technology for capturing water vapour from the air holds out hope for arid regions.

In April 2017, Prof Nair demonstrated that a multi-layer membrane made from graphene oxide can filter out the sodium chloride in seawater much more quickly and cleanly than existing techniques.

“The graphene filter is like a mesh or sieve with holes so small that salt molecules cannot pass through,” Prof Nair says. The filters were recently shown to be able to filter even the dye molecules of whisky, turning the liquid colourless. The university is in talks with potential manufacturers with a view to enlarging the membranes — currently A4-sized — and demonstrating that the technology can be used in practical applications.

“We have shown it works in the laboratory, now we want to demonstrate it in realistic conditions,” says Prof Nair. He hopes full-sized desalination plants with graphene membranes will be possible within five years.

Commitments to existing desalination technology may hold back large-scale commercial development of graphene systems in the short term, Prof Nair says. However, he thinks that a small scale version of the graphene filter can be developed for bottles and household units within two years.

To explore the possibilities, the university is collaborating with Icon Lifesaver, a company based in the east of England. The business currently makes filters that can remove microbes, bacteria and viruses. Joe Lovegrove, technical manager of Icon Lifesaver, says: “Graphene has the potential to create the ultimate filter that can also take out chemicals, solutes, salts and compounds such as pesticides.

“Its scope is absolutely massive. It would give us effectively the ultimate water filter that you could use to convert water at any source from being dangerous to safe as quickly as you can drink it.” Icon Lifesaver hopes to demonstrate that 400ml and 750ml bottles with easy-to-clean filters are viable for mass production. “People don’t want to spend time and effort cleaning,” says Mr Lovegrove.

“Initial studies are showing that all this is absolutely feasible with the graphene membrane — it performs superbly, better than anything else.”

Graphene filters would have the further benefit that they will not let any liquid through when they come to the end of their life.

“This is an advantage over many existing water filters where it is impossible to tell if they still work properly,” Mr Lovegrove says.

During the next few months, the portable graphene filters will be tested to check that they work for chemical contaminants such as cadmium, copper, arsenic, nitrites, nitrates and pesticides.

Once volume production is under way, the bottles are likely to cost £100 to £150 each. In arid areas, clean water production tends to focus on extracting moisture molecules from the air and cooling them down until they form droplets.

Currently this only works where humidity is at least 60 per cent. It is also very energy-intensive, says Beth Koigi, co-founder of Majik Water, a company set up to solve the problem. Majik Water uses desiccants — sponge-like materials such as silica gel — which extract water from the air. This is then released when the gel is heated. It can be re-used many times.

“Our prototype can work in humidity of just 35 per cent, and uses simple equipment and techniques to minimise energy demand,” Ms Koigi says.

Each device can generate 10 litres a day and runs on solar power. The goal is to produce clean water for a price of one cent per litre, far cheaper than bottled water or boiling water to purify it, while removing the risk of mineral contaminants.

Achieving the target price will depend on reducing the cost of the solar panels, which currently account for $1,000 of the $1,400 cost of a 20 litre device. After initial research in California, development has transferred to Kenya where the team is testing whether customers prefer household devices producing 20 litres a day or community systems generating more than 200 litres.

Research might continue in Kenya or move to the Atacama Desert Chile, the driest place on earth. Silica gel is abundant, safe and cheap, so it will help keep costs down. The team is also watching development of metal-organic frameworks (MOFs), which can hold up to three times their own weight in water, compared with 35 per cent for silica gel.

They could produce more water with less energy but are still at the stage of laboratory testing. At present they are expensive and unlikely to be widely available in the next five to 10 years.