From trash to treasure: Waste to energy explained

The world’s waste is more often associated with contributing to climate change – not helping to alleviate it. But in the race to decarbonize and reach net zero, waste-to-energy (WtE) systems — which use the heat from a waste plant’s combustion process to generate electricity — are gaining traction globally.

With a growing global population comes growing amounts of waste. Incinerating some of that rubbish helps to keep landfills in check. And with the world on track to produce 3.8 billion tonnes of waste by 2050, it’s not hard to see why this ‘trash to treasure’ technology appeals.

How does waste to energy work?

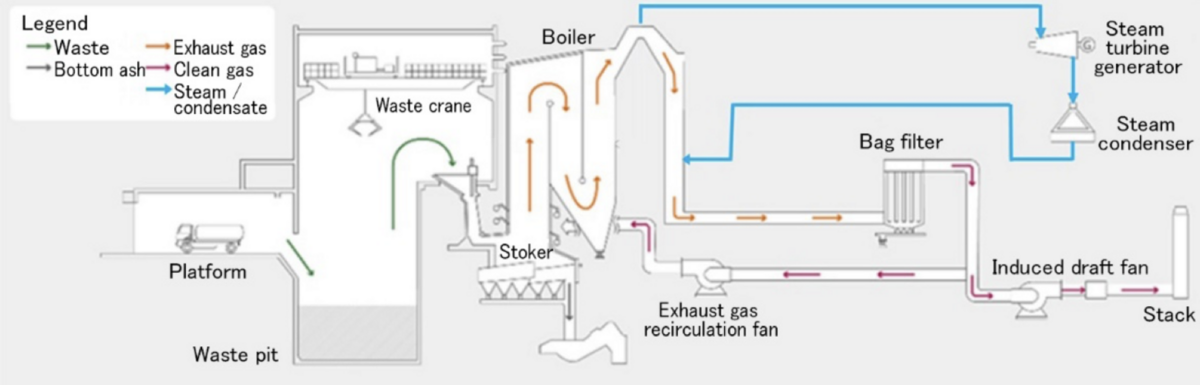

Once municipal waste has been sorted — with all recyclable and hazardous materials plucked out — the remaining materials are incinerated. With temperatures reaching over 1,000 degrees centigrade in a WtE plant, that’s a lot of potential energy generated. Instead of the resulting hot flue gases being pumped out into the environment, they are channeled through a boiler to heat water, the steam from which then generates electricity via a turbine. Meanwhile, the ash that settles at the bottom can be collected and used, for instance, in construction.

Critics say people should be encouraged to create less waste rather than find new ways to burn it. But with millions of tonnes of waste sent to the world's largest landfills every year, generating methane emissions, WtEs provide one way to deal with the issue. As an example, 85 pounds out of every 100 pounds of municipal waste in the US can be burned as fuel to generate electricity, reducing the volume of waste by about 87%, according to the US Energy Information Administration.

And, while incinerating waste inevitably produces pollutants, the latest WtE plants utilize air pollution control systems to reduce emissions.

The role of CCUS and other technologies

As well as shifts to reduce the amount of pollutants being emitted, efforts are also being made to reduce CO2 emissions. One strategy to achieve this is through the incorporation of Carbon Capture, Utilization and Storage (CCUS) technologies. Indeed, a recent analysis in the UK concluded that WtEs with CCS “have the potential of being negative emission technologies”.

Electricity isn’t the only energy the waste transformation process can produce. Waste-to-hydrogen (WtH) technology uses methods like gasification and pyrolysis to convert waste into hydrogen.

In Egypt, a WtH project is underway that will see 4 million tonnes of annual municipal waste transformed into 300,000 tonnes of green hydrogen. Oman has similar plans, with a $1.4 billion WtH project being built that is expected to produce 67,000 tonnes of green hydrogen a year.

The future of waste

WtE projects are popping up all over the world — from Australia to the UAE — and the market is growing rapidly. Valued at $44.3 billion in 2023, it is forecast to grow to $78.3 billion by 2032.

Sweden has been ahead of the game with its waste. Only 1% ends up in landfills, and WtE plants have been in operation there since the 1940s. Japan has been another WtE trailblazer, and MHIEC has recently agreed to reconstruct a WtE facility in Yokohama City, which involves dismantling and removing the existing structure and replacing it with three stoker incinerators. Set to open in 2031, it will be capable of processing 1,050 tonnes of waste a day.

MHIEC is also behind Singapore’s TuasOne WtE facility, which can incinerate 3,600 tonnes of waste and generate 120MW of electricity daily. It is one of multiple WtE plants in the city state that has been engineered, constructed and operated with 25 years of operation and maintenance (O&M) services by MHI Group.

With the world under pressure to decarbonize at pace, waste is at once an environmental, health and economic issue. WtE plants significantly decrease the volume of waste sent to landfills, as well as the methane released as that trash decomposes. Effective waste management as part of a circular economy could grow the global economy by $108.5 billion per year, according to a recent United Nations Environment Programme report.

As we navigate the complex challenges of our changing climate and resource scarcity, sustainable Waste-to-Energy technologies offer a multifaceted solution. By addressing waste management issues, generating energy and supporting the circular economy, WtE plants can play a crucial role in our transition to a more sustainable future.

Discover more about MHIEC’s latest case