Driving Innovation in an Uncertain World

We live in a ‘VUCA’ world. Facing inflation, recession, geopolitical upheavals and grim demographic trends, it has become a commonplace to state that levels of ‘volatility, uncertainty, complexity and ambiguity’ have reached unprecedented levels. And perhaps that is correct. What is certainly true is that societies and markets are changing rapidly and that the speed of change is accelerating.

In and of itself, this is not an issue. Change can be a powerful catalyst, spurring the development of new ideas, products and services. The problem is that it often ends up being the reverse: in the face of too much novelty and uncertainty, people cling to the familiar patterns of the past and grow more conservative, sometimes freezing altogether.

It is this that concerns me. As Chief Technology Officer at Mitsubishi Heavy Industries (MHI) Group, my job is to stimulate innovation. Yet, it has become clear that the traditional research and development methods of large companies like MHI are no longer the best way to create value in a volatile world.

Try, fail, try again

Two years ago, we confronted this problem head on, breaking up our R&D functions and forming hundreds of small, agile research teams, each focusing on one aspect of the 120 ‘megatrends’ we had identified as (re)shaping our customers’ business. Every team is given just three months and a limited budget to test an initial hypothesis. They then have to present their progress, defend themselves internally and in front of clients, revise their premise and try for another three months. This ‘pivot development’ process is repeated until it ends in failure or a workable prototype.

The new approach has far exceeded our expectations: in 24 months we have completed over 1,000 small trials, leading to 39 taskforces and 18 large new projects. Let me give just a handful of examples: we are working on micro data centers that need less power and generate lower emissions; we are turning used batteries from electric vehicles into energy storage reservoirs; and we are trialing a robot valet parking system at a shopping mall near Narita airport.

Despite these promising results, our internal efforts will only get us so far. That is why we emphasize ‘open innovation’ partnerships -- with other companies, government bodies, venture firms and academia. In fact, each pivot development team is actively seeking external help and this has enabled us to broaden our expertise to the point where MHI now works on over 700 technologies, including artificial intelligence and materials chemistry that go well beyond its heavy engineering heritage.

Finding the missing 10%

Conversely, the start-ups we collaborate with and invest in, can benefit hugely from our accumulated expertise. Often 90% of the necessary technology already exists inside MHI, the start-up contributes the missing 10% and as a result, development times can be compressed from years to months. In that sense, the evolution of machines is no different than that of organisms: both conform to Darwin's theory that combining and mutating genes (or here, technologies) produces new and better adapted products.

At our Yokohama Hardtech Hub, for example we are currently backing nine external start-ups and four internal projects. In the US, we have invested in a range of companies testing zero carbon fuels. Meanwhile, MHI's Innovation Accelerator is working with universities on 'blue sky' projects such as seeing if nuclear waste can be made safer.

Alongside collaboration, two other concepts are important to drive innovation in frontier technologies: selection and connection. As mentioned, large companies are treasury stores of knowledge and experience. At MHI, for instance, we have 33 business areas that make over 500 products based on more than 700 base technologies. The possible combinations are virtually infinite. Since our resources are not, we have to not only pursue agile development but also rigorous selection -- a process that involves not only our researchers and engineers but colleagues working on legal matters, intellectual property and much more.

We also need to include our customers of course. MHI, for example, has long been a world leader in CO2 capture technologies. But it was our clients that pushed us to standardize what are traditionally highly tailored installations, leading us to develop a series of modular CO2 capture systems that can be put in place in two days rather than over months.

Smart connections make machines smart

Such technology, however, requires advanced connections and co-operations, not only among business units inside a company, or between a manufacturer, its suppliers and customers; but also between machines and systems. While companies like ours are known primarily for their hardware, we also design and build the secure, fail-safe operating and control systems that run it. Using these to smartly connect machines – to the point where they become ‘smart machines’ – is the purpose of our ∑SynX concept.

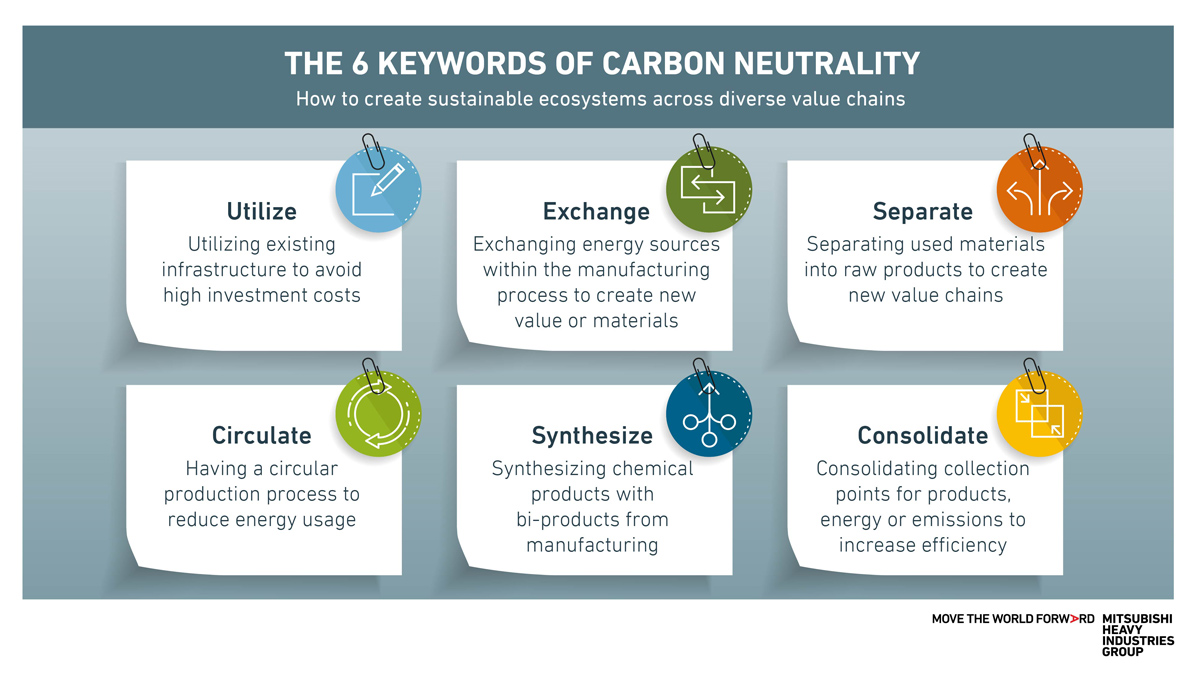

In our view, this is much more sophisticated system than the ‘dumb’ sensors being installed into products under the ‘4IR (Fourth Industrial Revolution)’ label. And this smart connection allows the creation of value chains across diverse industries for many purposes, but most importantly right now, to achieve carbon neutrality.

While all of this amounts to a promising future, we must pursue it in a realistic manner, taking care to balance the pursuit of innovation and environmental progress with energy security, economic efficiency and safety. Otherwise, neither our customers nor consumers at large will accept it.

We have an opportunity right now to do just that. Those of us managing corporations can use the public trust we have earned to showcase a future that is technologically advanced and allows a higher quality of life while remaining safe and reassuringly familiar. That is worth striving for, and will enable us to continue building up further trust.