Achieving net zero: What is turquoise hydrogen?

Despite the pandemic, the quest for net zero emissions and halting global warming has never left the headlines. Quite the opposite: achieving the 2050 climate targets has become inextricably linked with the recovery from COVID-19 – a chance to “build back better”.

Policymakers, energy firms and scientists are hoping to use carbon-free ‘green’ hydrogen as a fuel of the future for power generation, long-haul transportation and industry. But despite significant advances, the hydrogen market needs a major boost if it is to play a key part in the race to net zero.

A new technology referred to as ‘turquoise’ hydrogen production could be what is needed to fast-track its development.

The hydrogen challenge

While hydrogen burns CO₂-free, its predominant production methods still use fossil fuels, including steam methane reforming from natural gas. This entails significant CO₂ emissions.

Hydrogen can be produced carbon-free by using excess renewable power – from wind or solar plants – to extract the gas from water via electrolysis. The underlying technology is well-developed but has only been deployed on a small scale. In 2019, a mere 0.1% of global hydrogen was produced by electrolysis. Though 2020 saw a record increase in announced production capacity, green hydrogen still has a long way to go.

So, if sectors as diverse as power generation, industry and transportation opted for hydrogen on a significant scale, where would it all come from? Until electrolysis powered by renewable-energy sources is ready to pick up the slack, a ‘stopgap’ is needed to help synthesize hydrogen at the required scale.

Policymakers including the European Commission are encouraging not only green, but also ‘blue’ production methods. These combine traditional, fossil-fueled synthesis with carbon capture technology to filter out the CO₂ generated before it hits the atmosphere.

A new contender is turquoise hydrogen, so called because the method of synthesizing it is regarded as sitting somewhere between green and blue hydrogen production.

What is turquoise hydrogen?

Turquoise hydrogen uses a process called methane pyrolysis, which directly splits methane – the main component in natural gas – into hydrogen and solid carbon. Also called ‘carbon black’, this byproduct has a variety of industrial applications, including in the production of car tires, coatings, plastics and batteries, and is considered a critical raw material.

Methane splitting is not a new concept, and a few commercial-scale plants already exist in North America. Countries including Australia, Russia and some European nations are also working on scaling the technology.

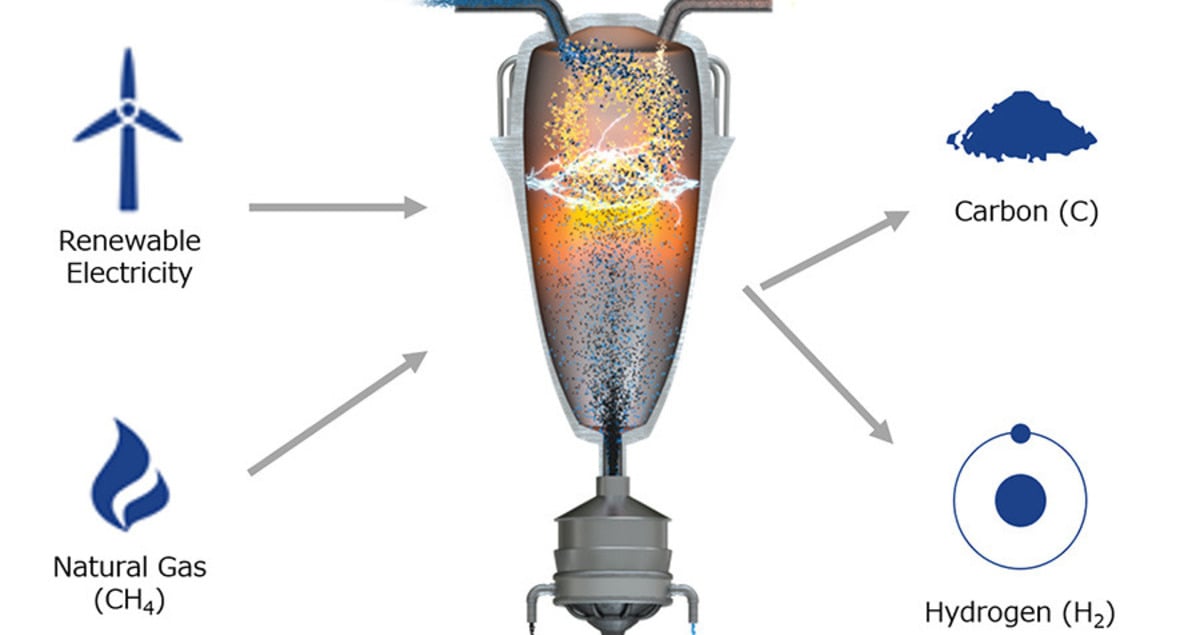

The process uses natural gas purely as a feedstock, with all energy for heating and splitting methane coming from electricity. So if the electricity is sourced from renewable energy, the whole process is basically carbon neutral.

A few steps closer to green hydrogen

In Nebraska, US, Monolith Materials already runs a commercial-scale, emissions-free production facility which will produce clean hydrogen alongside around 14,000 metric tons of carbon black per year. The company is also planning to synthesize emissions-free ammonia at a second production site.

Its process works by superheating natural gas using renewable electricity. The heat separates the carbon and hydrogen atoms that make up the gas molecules. The carbon atoms start to cluster together to form carbon black. A filter unit then separates hydrogen and carbon black; they are then stored and prepared for onward use.

The operation is expected to lower emissions from hydrogen and carbon black by up to 97% compared to the products’ traditional manufacturing processes.

Mitsubishi Heavy Industries (MHI) Group has recently invested in the company and has since also backed another start-up company, C-Zero, to strengthen its hydrogen-energy value chain strategy.

C-Zero is focused primarily on producing hydrogen and sequestering solid carbon, rather than producing a high-end product like carbon black. It aims to bring the cost of turquoise hydrogen down to the same price as traditionally synthesized (‘grey’) hydrogen today, making it more attractive to buyers.

A game changer for hydrogen?

Turquoise hydrogen has been touted as a game changer.

One major factor here is that the methane pyrolysis process does not result in any CO₂ emissions, so there is no need to invest in carbon capture facilities and no need to worry about where to store it.

Especially while electrolyzer capacity worldwide is building up, methane pyrolysis could provide another effective route towards generating carbon-free hydrogen, helping to build the hydrogen value chain.

The production of carbon black will be part of this value chain, but what is more, it has the potential to change the economics of hydrogen production by virtue of selling a high-value raw material alongside. A potential pathway for the production of ammonia – which is used in fertilizers – adds to the attractiveness of the turquoise hydrogen proposition.

Finally, the process uses electricity to provide the industrial heat needed, and this could be met entirely by renewable sources. This makes methane pyrolysis particularly suited to countries with both large natural gas reserves and good access to renewable energy - and potentially throws them a new commercial lifeline with the production of carbon black.

Hydrogen is now regarded as a key fuel in the race to reach net zero targets across the globe. Turquoise hydrogen may offer one more way of hitting these targets faster and sooner - as well as a sustainable business over the long term.

Discover more about MHI work with Monolith Materials